Exploring the Collaborative Process of Metal Machining and Impact Extrusion in Production!

In the realm of manufacturing, two processes have proven to be a formidable duo in producing strong and precise parts: impact extrusion and machining. These techniques, when combined, allow for the creation of parts that not only boast impressive strength but also intricate details, tailored to meet the demands of real-world needs.

Impact extrusion, a high-speed, forceful process, moulds heated metal (such as brass) into near-net-shape parts. This is achieved by applying a powerful hit to the metal, which is then pressed through a die, forming hollow tubes or complex profiles with excellent mechanical strength and smooth surfaces [1][4]. This process also induces compressive stresses within the material, enhancing its strength and fatigue resistance [4].

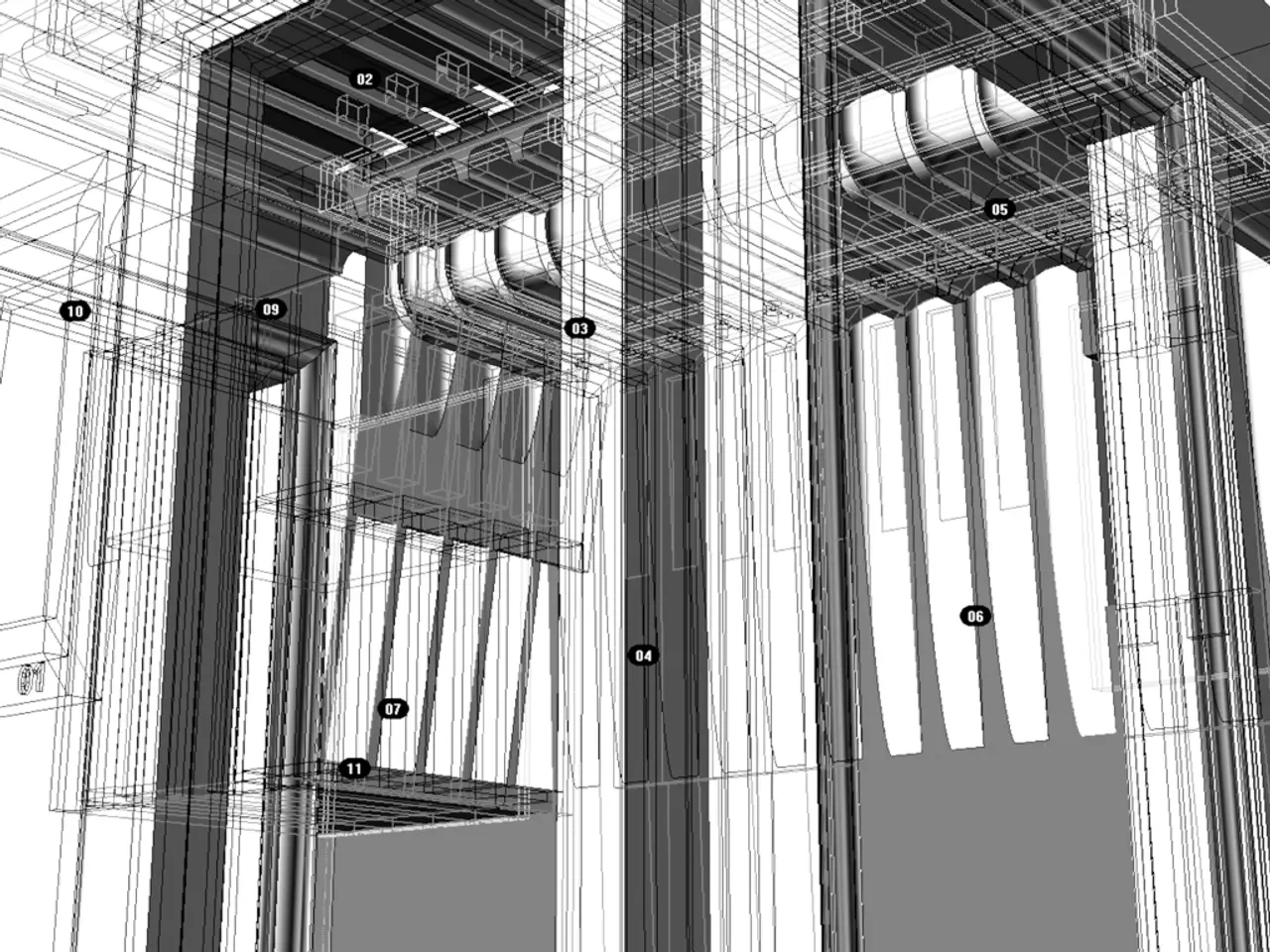

Following impact extrusion, machining comes into play. This process, which involves the removal of small amounts of material from the extruded part, allows for the addition of detailed features, tight tolerances, or surface finishes that would be unattainable through extrusion alone [4]. This includes the creation of precise holes, grooves, threads, or the achievement of dimensional accuracy necessary for the final application.

The combination of impact extrusion and machining offers a unique balance. Impact extrusion forms the strong, shaped base part efficiently, while machining refines it with detailed, exact specifications, ensuring the final product meets the desired complexity.

This partnership works best for medium or high volumes, as the upfront cost of extrusion tooling is high. However, the efficiency of extrusion presses, which operate at high speeds, helps lower per-part costs for these volumes [4].

It is worth noting that impact extrusion is a cold forming process, which uses a punch to force a piece of metal into a die, shaping it. This process is particularly effective with soft metals like aluminum, zinc, or copper [4].

The automotive, consumer packaging, electronics, and energy industries are among those that frequently utilise impact extrusion and machining to produce strong, precise parts. Yet, it is crucial to choose the right metal, as not all metals work well with both processes [4].

Common products manufactured using impact extrusion include aluminum cans, deodorant tubes, automotive sensor housings, battery sleeves, and medical containers. This testament to the versatility and widespread application of impact extrusion and machining in modern manufacturing.

- The finance sector has a crucial role in supporting the manufacturing industry, as the high upfront cost of extrusion tooling for impact extrusion and machining processes can be offset by efficient production in medium or high volumes.

- The integration of technology, particularly in the form of advanced simulations and CNC machines, plays a vital role in the precision and detailing of parts produced via the combined impact extrusion and machining processes, ensuring their compatibility with various industries such as automotive, consumer packaging, electronics, and energy.