Importance of oxygen balloons in contemporary electronic structures

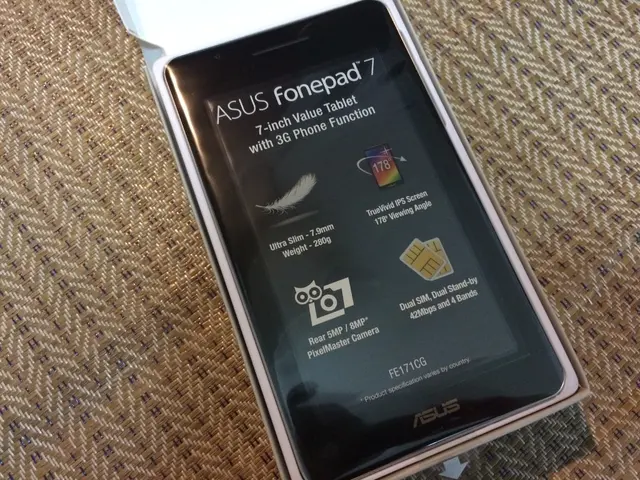

Handheld label printers have become an indispensable tool in modern workplaces, offering a versatile solution for labelling items on-site. These compact and lightweight devices are ideal for use in warehouses, retail, manufacturing facilities, electrical and construction work, and even home use.

The Economical and Convenient Label Printer

The handheld label printer offers a variety of font and symbol options, providing users with the flexibility to change texts, fonts, and label sizes according to their needs. Furthermore, these printers are powered by rechargeable or regular batteries, ensuring portability and uninterrupted use.

Oxygen Cylinders: Ensuring Safety and Reliability

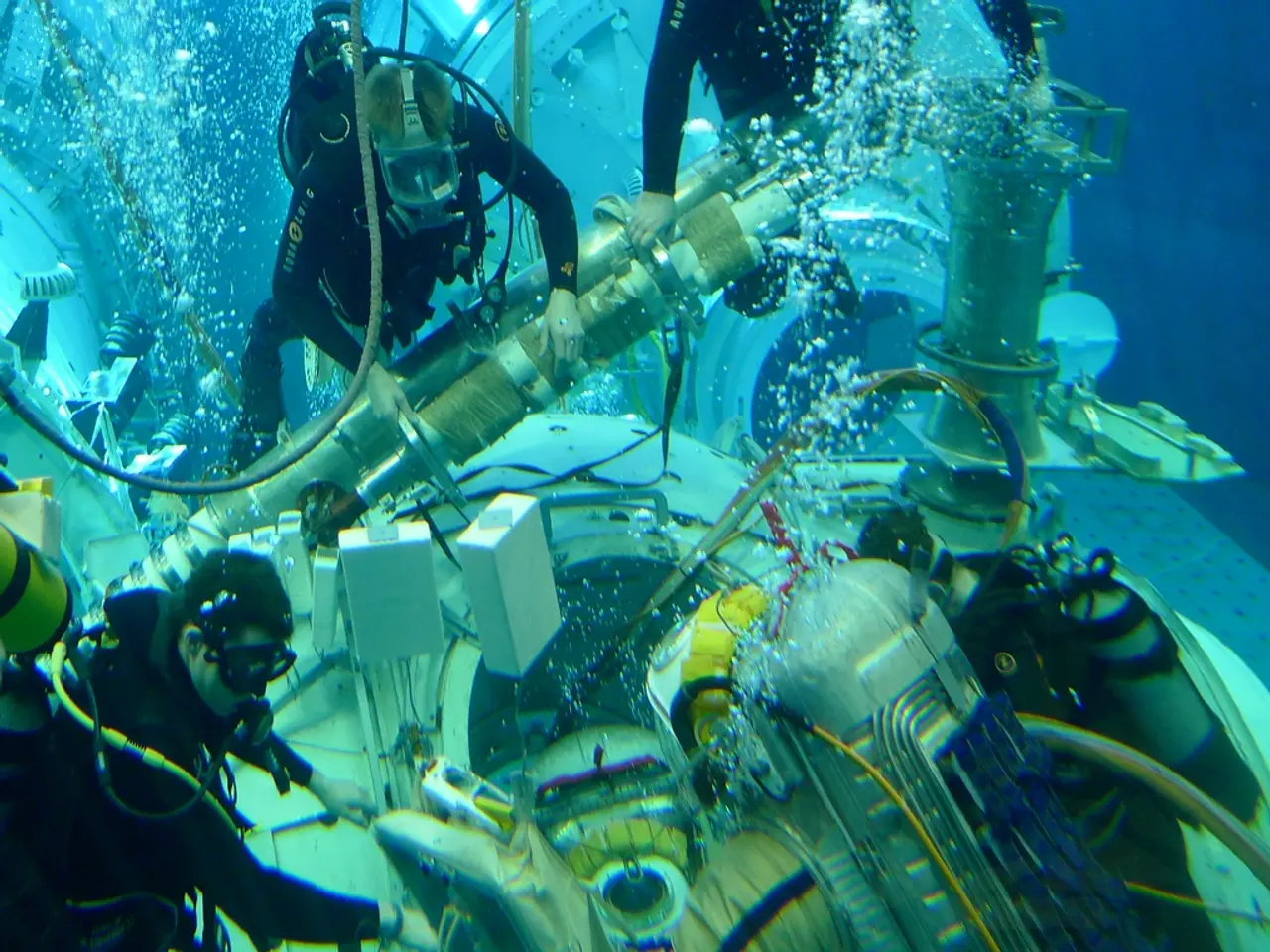

On the other hand, oxygen cylinders play a crucial role in various fields, from medicine and rescue operations to industrial processes and welding works. The production of oxygen cylinders involves several key stages to ensure safety, reliability, and tailored applications.

Stages in Oxygen Cylinder Production

- Oxygen Production: This stage involves either fractional distillation of air (cryogenic distillation) or pressure swing adsorption (PSA) to separate oxygen from ambient air and produce high-purity oxygen gas.

- Purification and Quality Control: After production, oxygen is purified to meet specific grades required for its application. This step typically includes filtering, moisture removal, and final quality checks.

- Compression and Storage: Oxygen gas is compressed into high-strength steel or aluminum alloy cylinders, designed to withstand high pressures. Safety features such as pressure relief valves and color coding for identification are added at this stage.

- Cylinder Filling: Compressed oxygen is filled into cylinders using controlled processes to maintain purity and avoid contamination.

- Testing and Certification: Each cylinder undergoes rigorous testing for leakages, pressure resistance, and durability to comply with national and international safety standards. Medical oxygen cylinders have additional certifications for healthcare usage.

- Distribution and Application Specific Preparations: Cylinders are then delivered to end-users where they may be fitted with delivery devices suitable for their intended use, such as regulators, nasal cannulas, masks, ventilators, welding torches, or advanced welding and structural processes.

In healthcare, oxygen cylinders provide respiratory support to patients with breathing difficulties, chronic respiratory diseases, or during surgical procedures. In industries like metal cutting, welding, and chemical processing, oxygen cylinders ensure precise oxygen delivery, facilitating controlled burning in welding torches and metalworking. Special response teams and rescue organizations rely on oxygen cylinders during fire fighting and hazardous material incidents.

Both handheld label printers and oxygen cylinders serve essential purposes in their respective fields, underscoring the importance of practical, efficient, and safe solutions in various industries.

Choosing the Right Handheld Label Printer

When selecting a handheld label printer, consider factors such as the width and length of the ribbon, battery life, language, font, and symbol support, and additional features like automatic cutting, barcode printing, and mobile device compatibility. It's essential to choose a printer that meets your specific needs and requirements for labelling efficiency and accuracy.

Remember, no special training is required to use a handheld label printer, making it an accessible solution for businesses and individuals alike. The labeling process with a handheld printer takes mere seconds, saving valuable time and resources in the long run.

[1] Oxygen Production Methods. (n.d.). Retrieved from https://www.oxygen-plant-manufacturers.com/oxygen-production-methods/ [2] Liquid Oxygen Storage and Transport. (n.d.). Retrieved from https://www.oxygen-plant-manufacturers.com/liquid-oxygen-storage-and-transport/ [3] Pressure Swing Adsorption (PSA) Oxygen Generators. (n.d.). Retrieved from https://www.oxygen-plant-manufacturers.com/pressure-swing-adsorption-psa-oxygen-generators/ [4] Oxygen Generator for On-Site Production. (n.d.). Retrieved from https://www.oxygen-plant-manufacturers.com/oxygen-generator-for-on-site-production/ [5] Oxygen Cylinder Manufacturing Process. (n.d.). Retrieved from https://www.oxygen-plant-manufacturers.com/oxygen-cylinder-manufacturing-process/

- What technology powers these handheld label printers to ensure portability and uninterrupted use?

- Technology, in the form of rechargeable or regular batteries, is utilized in handheld label printers to maintain their portability and provide uninterrupted use, making these devices a versatile and practical solution for labeling needs across various industries.