Optimizing Mechanized Construction: Boosting Efficiency and Creativity

Automation Machine Design: Shaping the Future of Industries

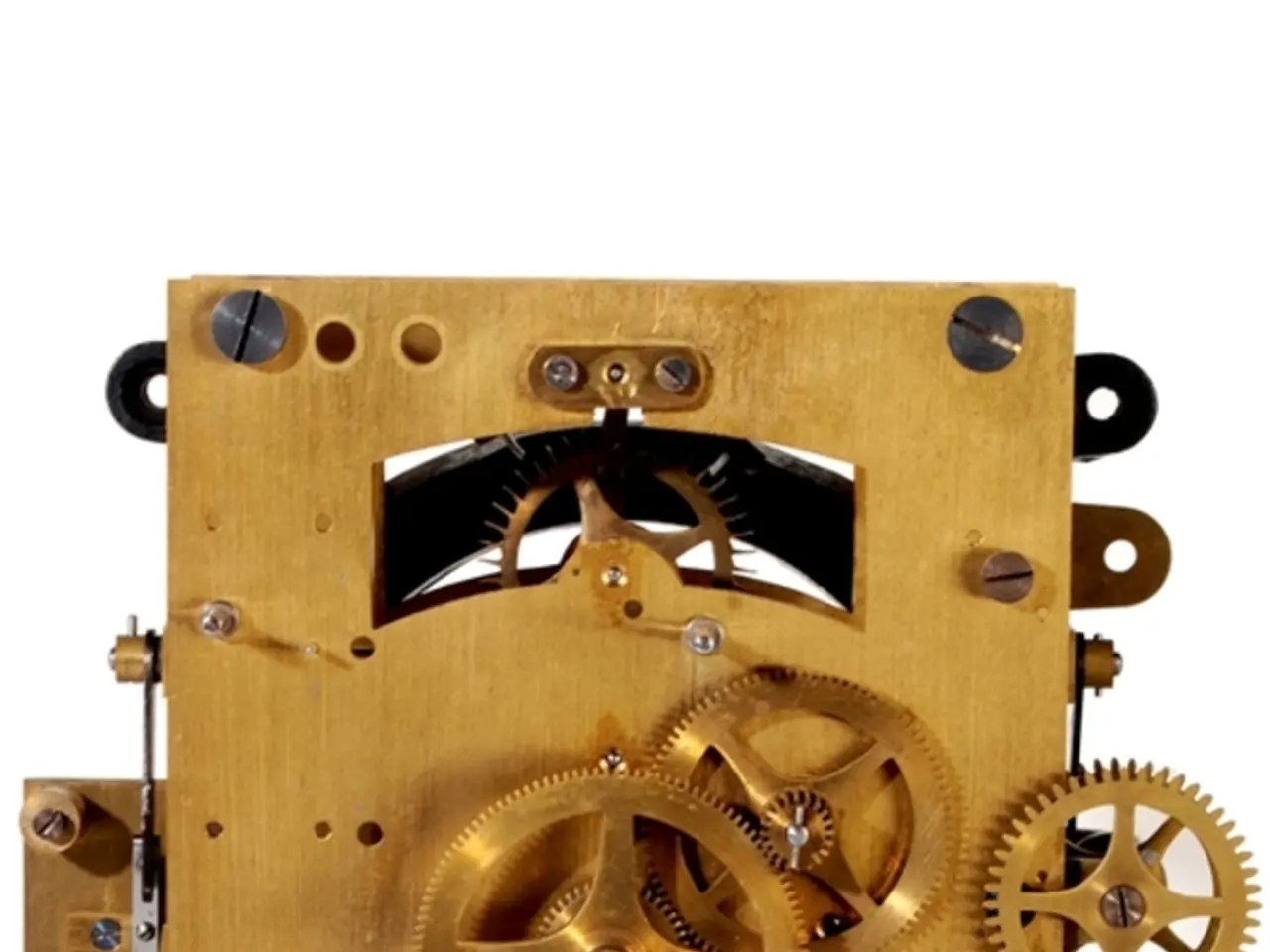

Automation machine design, a critical aspect of modern manufacturing, is transforming industries worldwide. This innovative approach involves the integration of sensors, actuators, control systems, robotics, software, and seamless component integration for efficient operation.

The primary application of automation machine design is in manufacturing, logistics, and various industries where high-volume production is essential. By automating tasks, companies can reap numerous benefits, including reduced labor costs, fewer errors, and less waste, contributing to lower operational costs.

Automated systems are not just limited to assembly; they handle the packaging, labeling, and quality control processes as well. In food processing, for instance, automation ensures products are packaged efficiently and consistently while maintaining hygiene and quality standards. Similarly, in drug manufacturing, automated machines help maintain compliance with stringent regulations.

One of the most significant advantages of automation is its precision. Automated machines can perform high-precision inspections, identifying defects or deviations in products with high accuracy. This is evident in the aircraft manufacturing industry, where automation is used for precision assembly and inspection of complex components.

In the automotive sector, automation systems are used in car assembly lines, performing tasks like welding, painting, and assembling parts with precision. These systems can also be equipped with vision systems and sensors to continuously monitor product quality and make adjustments in real-time.

Moreover, automation systems can significantly boost production rates and throughput. They can move materials across production lines, reducing the need for human labor in this often repetitive task. This increased efficiency allows manufacturers to reduce costs, improve product quality, and speed up production, helping them remain competitive in a global market.

However, automation machine design does have its disadvantages. The high initial cost, complexity in setup, maintenance requirements, and limited creativity are some of the challenges associated with automation. Nevertheless, current trends in automation machine design aim to address these issues.

Current trends center on integrating advanced technologies like Artificial Intelligence (AI) and Machine Learning (ML), Industrial Internet of Things (IIoT), and collaborative robots (cobots). These trends highlight the growing use of predictive analytics, digital twins, and advanced human-machine interfaces to enhance operational efficiency, reduce downtime, and improve real-time decision-making in manufacturing environments.

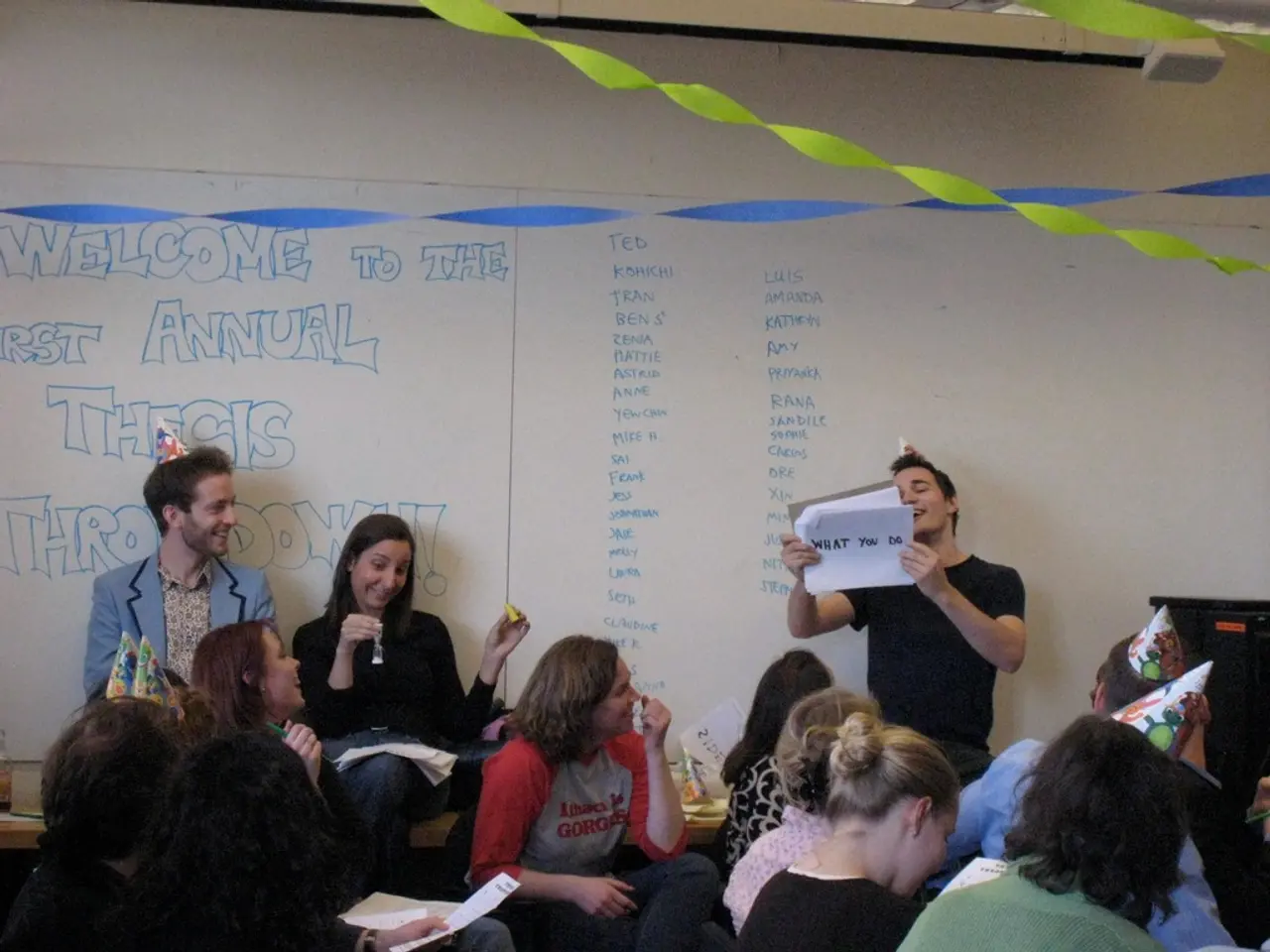

Key developments include predictive maintenance, leveraging AI and IIoT sensor data for real-time condition monitoring and error prevention. Another trend is hyperautomation, combining data analytics, AI, and automation tools to manage entire workflows and supply chains. Collaborative automation, where cobots work alongside humans to automate repetitive tasks, is also gaining traction, consistent with the emerging vision of Industry 5.0, which emphasizes human-machine collaboration and sustainability.

For future developments, automation machine design is expected to further evolve with an increasing use of automatic process discovery and self-optimizing workflows that adapt based on performance data. There will also be deeper incorporation of natural language processing to simplify automation design and deployment. Emphasis on resilience, sustainability, and inclusiveness, with machines complementing human creativity and intuition, is also anticipated.

In summary, automation machine design is trending toward more intelligent, interconnected, and human-augmenting systems that enhance productivity while fostering worker collaboration and sustainability. These directions reflect a maturation from the purely machine-centric Industry 4.0 into the more balanced and inclusive Industry 5.0 paradigm.

Automation machine design is increasingly integrating advanced technologies like Artificial Intelligence and Machine Learning, aiming to address its initial high cost and maintenance requirements.

In the future, automation machine design is expected to incorporate natural language processing, improving the simplicity of automation design and deployment.