Primarily Adopted Motivations Behind Machine Design Firms Opting for Sophisticated Approaches

In the rapidly evolving world of machine design, companies are increasingly turning to advanced solutions to streamline their processes, foster innovation, and reduce costs. A newly released document provides valuable insights into the advantages of implementing these cutting-edge tools, offering strategies and actionable advice to help overcome common industry challenges.

The document, designed to help companies elevate their design capabilities, emphasizes several key benefits associated with the use of advanced design solutions. Improved efficiency and reduced costs are at the forefront, as advanced tools are engineered to optimize workflows and eliminate redundant tasks, leading to faster design cycles and significant cost savings. By identifying issues early in the design process, companies can avoid costly rework and reap substantial savings[1][3].

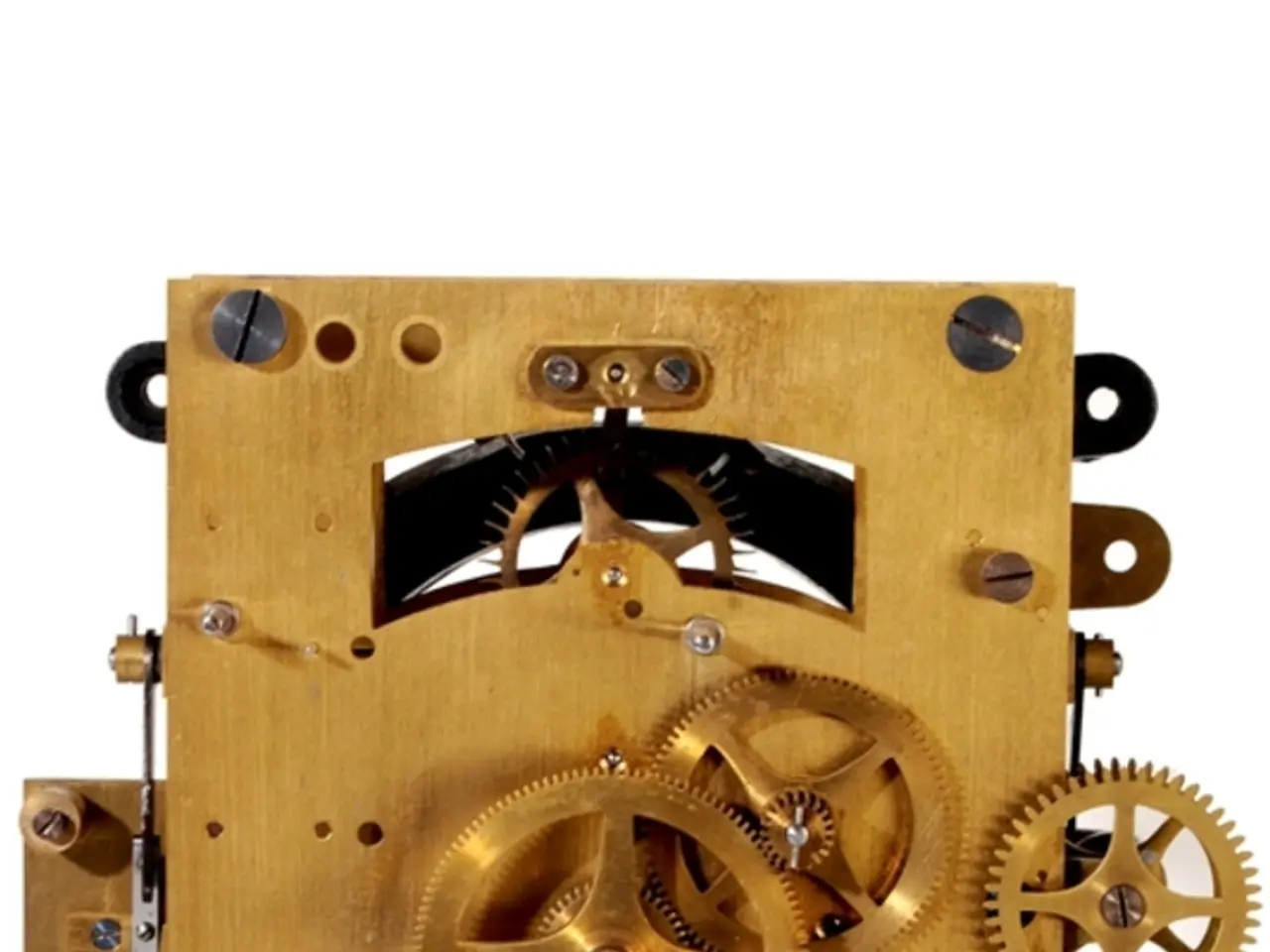

One of the most compelling advantages of advanced design solutions is the ability to deliver superior project outcomes. With sophisticated simulation, modeling, and digital testing capabilities, companies can validate designs virtually before committing physical resources. This reduces errors, enhances product quality, and accelerates time-to-market[1][2].

Another advantage highlighted in the document is early mechanical variation management. Tools that allow engineers to incorporate mechanical variation and tolerance analysis at early stages help avoid production problems related to tolerancing. This leads to better product robustness and decreases downstream manufacturing issues[3].

The document also underscores the importance of facilitating innovation in the machine design process. By integrating advanced simulation and AI technologies, machine design companies can explore creative solutions and optimize complex designs. AI, in particular, is gaining traction for its ability to transform manufacturing operations, improve decision-making, and kickstart data-driven process improvements[4].

Collaboration and communication within engineering teams and stakeholders are also enhanced through the use of modern design platforms. This ensures that design intent and engineering parameters are clear and adhered to throughout product development[3].

Data-driven and smart automation integration is another key aspect of advanced solutions. Incorporating sensors, connectivity, and cloud computing technologies helps in real-time monitoring of machine health, predictive maintenance, and automation, which further boosts efficiency and safety while reducing downtime[2].

Accelerated time-to-market is another significant benefit, as simulation and digital twins enable companies to iterate designs rapidly and test production scenarios virtually, enabling faster product launches and reducing development risks[2][1].

In summary, the document demonstrates that machine design companies choose advanced solutions primarily because these technologies enable them to design more efficiently, innovate confidently, reduce costs, and bring superior, high-quality products to market faster. They also foster greater collaboration and leverage data-driven insights and automation to streamline the entire design and manufacturing lifecycle[1][2][3][4].

For companies looking to propel themselves forward in the machine design field, this downloadable content offers a wealth of insights and strategies to help overcome common industry challenges and capitalize on the benefits of advanced solutions. By embracing these tools, companies can position themselves for success in the competitive machine design landscape.

Advanced solutions in data-and-cloud-computing technology play a crucial role in the evolution of machine design, facilitating innovation, reducing costs, and enhancing efficiency by optimizing workflows and eliminating redundancies. These tools enable companies to design more efficiently, innovate confidently, and minimise errors, ultimately leading to superior project outcomes.

By integrating AI, smart automation, and modern design platforms, companies can foster collaboration within engineering teams, generate data-driven insights, and streamline the entire design and manufacturing lifecycle, thus positioning themselves for success in the competitive machine design landscape.