Quasi-Direct-Drive Motor Model Based on MIT's Mini Cheetah Robot's Design

### Caden Kraft's Innovative Quasi-Direct-Drive Actuator: A Cost-Effective Solution for Robotics

In the world of robotics engineering, Caden Kraft has made a significant breakthrough with his latest invention - a quasi-direct-drive (QDD) actuator. This innovative design combines the precision and responsiveness of direct-drive actuators with the power density of traditional actuators, offering a cost-effective solution for various applications.

### Materials and Design

The actuator's structural components are primarily made of lightweight yet robust materials such as aluminium or carbon fibre. High-quality rare-earth magnets, like neodymium, are used for the motor components to ensure efficient energy conversion. The gear components are made from high-strength, low-friction materials such as titanium or advanced polymers to ensure durability and efficiency. The outer casing is made of durable plastics or metals to protect the internal components.

### Cost-Effective Manufacturing

The cost of the actuator can vary significantly depending on the scale and application. However, advancements in manufacturing technologies, such as 3D printing, can help reduce costs. Caden Kraft himself used 3D printing for most of the actuator's custom parts, excluding the backing iron for the permanent magnets. The total cost of the entire actuator was reportedly less than $80.

### Performance and Efficiency

The actuator boasts a high torque output for its size, making it suitable for applications requiring both strength and precision. The quasi-direct-drive design allows for high efficiency by minimising energy loss through gear friction. The actuator is also capable of fast and precise movement, ideal for applications requiring rapid changes in velocity.

In a test, Caden Kraft's actuator provided 29.4 Nm of torque when connected to an EV battery module, almost three times his initial goal. However, during the first test, the actuator failed due to drawing more current than the power supply could provide.

### Unique Features

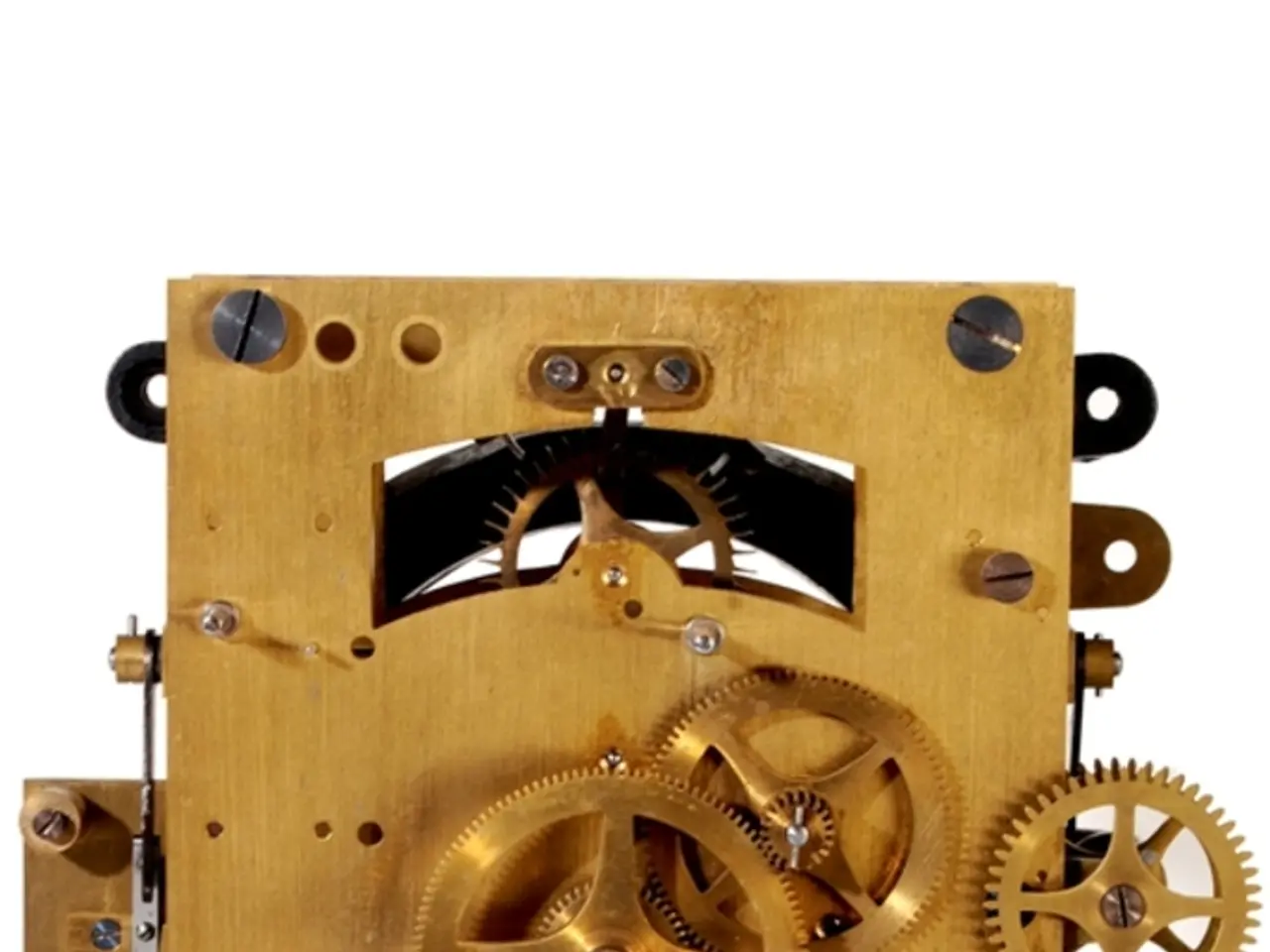

Caden Kraft's design includes several unique features. He used a planetary gearbox with cycloidal gear profiles, which reduce backlash, decrease stress concentration on the teeth, and are easier to 3D print. Instead of a backing iron, Caden arranged the magnets to form a Halbach array, providing nearly identical performance to a motor with a backing iron.

Caden also developed a Python program to generate planetary gearbox designs, which he later modified to export 3D files. This tool could potentially streamline the design process for other engineers working on similar projects.

### Applications

The actuator's high precision, speed, and strength make it suitable for various applications, including robotics, automation systems, and medical devices. In particular, it could be used in robotic arms or grippers, manufacturing lines requiring high precision, and precise medical equipment such as surgical robots.

### Conclusion

Caden Kraft's quasi-direct-drive actuator design offers a cost-effective solution for robotics engineers seeking a balance between precision, power density, and cost. With its unique features and customisable specifications, this actuator could revolutionise various industries by providing affordable, high-performance solutions.

In the realm of DIY technology and gadgets, Caden Kraft's open-source Python program for generating planetary gearbox designs could prove invaluable, potentially simplifying the design process for enthusiasts and professionals alike in data-and-cloud-computing or robotics. The cost-effective manufacturing of Caden Kraft's actuator, utilizing advanced technologies such as 3D printing, showcases a promising future for DIY hardware in the world of technology.