Solid 3D Printed Milling Machine Showcases Resilience

Building a CNC milling machine isn't everyone's cup of tea, but if you're up for some DIY innovation, check out [Chris Borges]'s badass, concrete-infused CNC mill.

This machine's outer shell, a 3D-printed beauty, doubles as a mold for the concrete innards. Inside the concrete lies a steel frame, with rebar crafted from threaded rods and a length of square tubing to keep the main column solid. Catch a glimpse of the concreting process in the video below or feast your eyes on the images.

A true mill newbie, [Chris] has managed to produce a machine that's as impressive as it is docu-mented, with a detailed Bill of Materials and a 45-page step-by-step instruction manual. If you're bent on creating your own version of this beast, give that guide a read.

Chris has a knack for wacky projects, as you might recall from stumbling upon his concrete lathe on our pages. This isn't the first CNC mill project we've highlighted either.

Wanna get experimental with similar concepts? Here's some food for thought.

CNC Milling Machines

CNC milling machines are industry workhorses, precision-cutting and shaping materials like wood, metal, and plastic. DIYers often adapt them for projects involving composites or hybrid materials.

Concrete and Hybrids

Concrete projects focus on creating composite materials or structures. Enhancing concrete's strength and durability with fibers like glass or steel is common in construction and engineering fields.

DIY Projects

DIYers love to get creative with their tech, repurposing and experimenting with unconventional materials or designs. Integrating concrete into a DIY CNC project, for artistic or functional purposes, could be your next big thing.

If you're keen on a project like a "Concrete-filled CNC mill," explore how to modify CNC tech for working with concrete or similar materials. Designing custom fixtures or using the CNC machine to shape molds for concrete casting could be your ticket to DIY success. But specific details about Chris Borges' project are scarce. Luckily, DIY forums, blogs, or specific maker communities are the perfect places to find info about such innovative projects. Good luck, and happy experimenting!

- For those intrigued by the idea of integrating concrete into DIY projects, you might consider modifying CNC technology to work efficiently with such materials.

- If you're captivated by the notion of creating a DIY project akin to Chris Borges' "Concrete-filled CNC mill," delve into designing custom fixtures or using the CNC machine to shape molds for concrete casting, a possible pathway to DIY success.

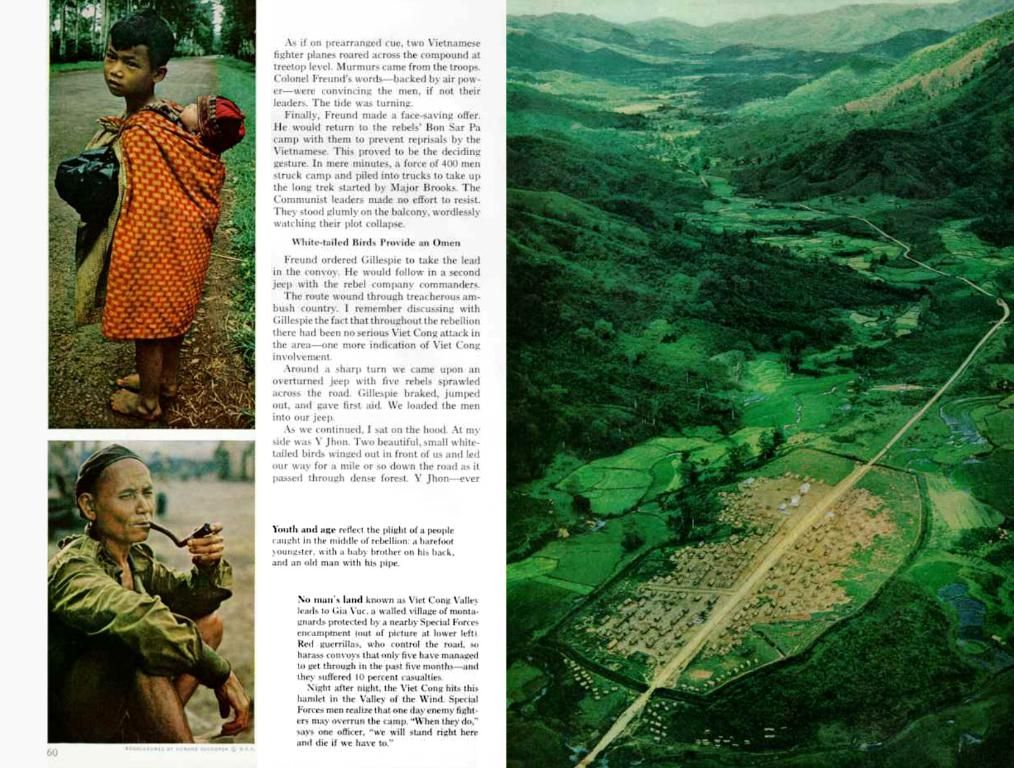

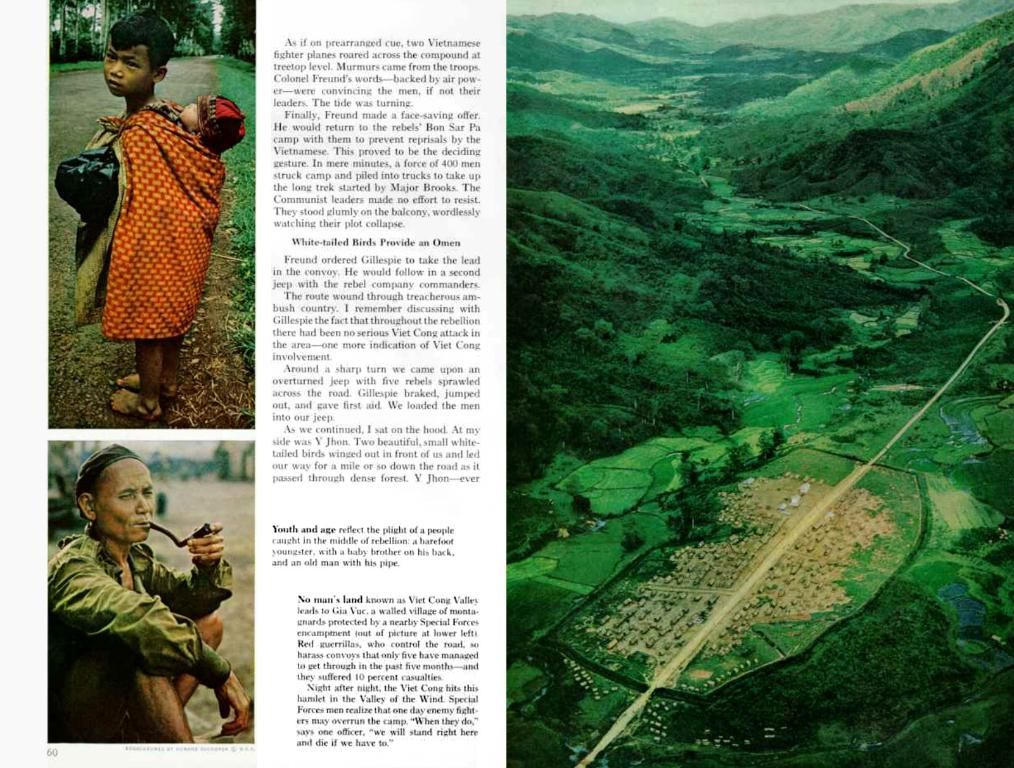

![DIY enthusiast, [Chris Borges], opted for an unconventional approach when constructing a sturdy...](/en/img/2025/06/04/065405/jpeg/4-3/1200/75/image-description-sunset-beach-palm-trees-ocean-sand-beautiful-landscape-vacation-travel-tourism.jpeg)